Profile Metallization

Types of metallization

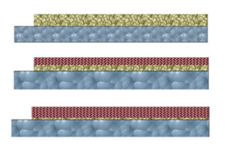

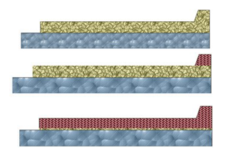

- 3. Profile Metallization, Wide Heavy-Edge

The best possible compromise and optimisation on low electrical losses and high break down voltages can be achieved by combining a wide heavy-edge with high Ohms on the surface at the free margin side. A wound capacitor must always have one of the two films with a good self-healing behaviour using a high resistive area; typically 1/3 low resistivity and 2/3 high resistivity are designed over the film width.

In collaboration with our customers we precisely define the resistance profile by a drawing.

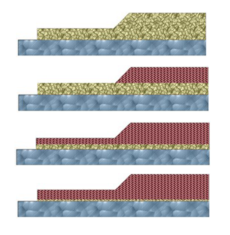

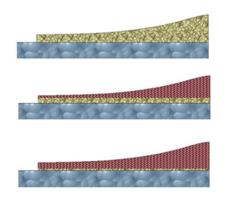

- 4. Profile Metallization, soft transition, linear resistance

Metallization, with a defined profile of the surface resistance (= Rs), allows the minimisation of the losses at each and every single point inside the capacitor (Pr = I² Rs).

During the design phase the tan. δ, self-healing and breakdown voltage can be rated and optimised mathematically. A profile drawing with the precise resistance profile will then be provided to our customer.

Remarks:

The sketches symbolise the metallized layers of aluminium (yellow) and zinc (red). In the profile drawings provided by us the surface resistance is normally illustrated reciprocally.