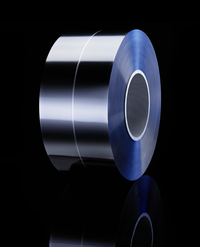

Metallized BOPP film

Steinerfilm® P is based on Biaxially Oriented PolyPropylene = BOPP film. This film is offered in various metallizing patterns and individual slit widths for highly customised capacitors and applications.

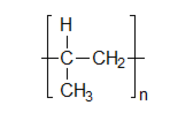

The molecule showing above is the base for all polypropylene materials. The specific arrangement of the molecules, the length of the chain and the orientation of the “ - CH3 “ branch separate today’s materials from other PP-material. These films differ from other technical films due to the highest purity and the absence of additives like fillers or softeners.

A frequently asked key performance indicator for film capacitors is the specific capacitance. This ratio deals with the microfarad per volume and scales with one over thickness square. That pursues the target of the thinnest possible gauge.

The spectrum of film thickness is at the bottom end of all ”technical” films. The thickest OPP for capacitor application is about 20 µm ( = 0.020 mm ). Actually the thinnest commercially available gauge for an OPP film is about 1/13th of this e.g. 1.6µm = 0.0016 mm !

Capacitors made with a 2 micron film give 5 µF/cm³.

The self-healing capability separates film capacitors from all other capacitor types. This finally ensures a high reliability and long life of these devices and safety in their applications.

Another key performance indicator for film capacitors deals with energy density. This ratio scales with volt per micron square. That pursues the target of a maximum electrical field stress even at high temperatures.

Steiner’s coating technique implements this in highly customised metallizing patterns that in parallel minimise the risk of excessive self-healing.

This makes Steinerfilm® P a step ahead for a wide spectrum of applications, starting with traditional DC and AC 50/60 Hz up to the latest so called DC link applications. These inverters/converters deal with high DC voltages plus a high frequency AC ripple.